该App用于在缝制组线上,记录组检的检验结果。

This App is used to record the inspection results of in-line group inspectors on the sewing production line.

¶ QC检查点的设置方法 Methods for Setting QC Checkpoints

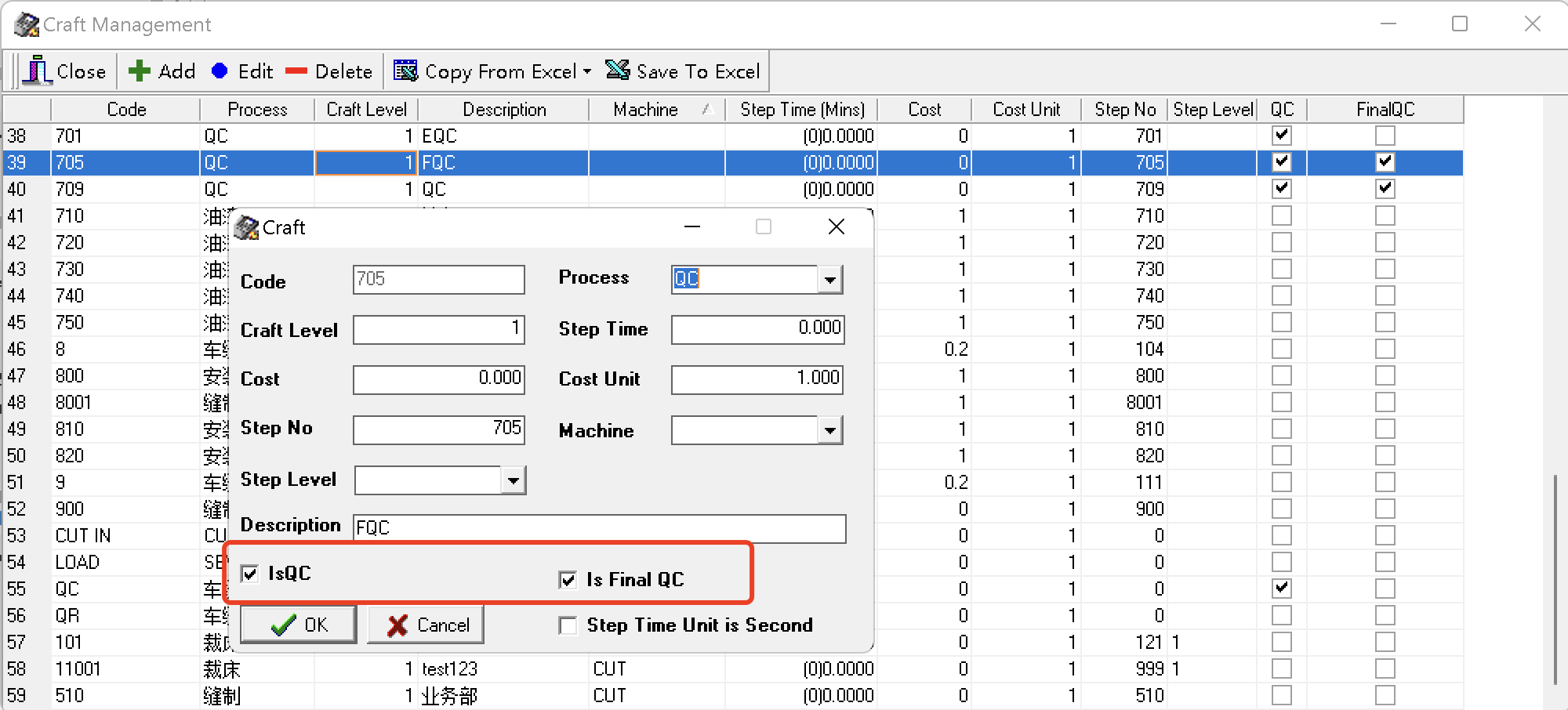

- 系统识别QC工序的标志:岗位工艺

需先新增QC岗位工艺,需勾选“Is QC”。可设置多个QC岗位工艺。

System identification mark for QC processes: WorkOperation

First, a new QC WorkOperation needs to be added, and "Is QC" should be checked. Multiple QC WorkOperation can be set.

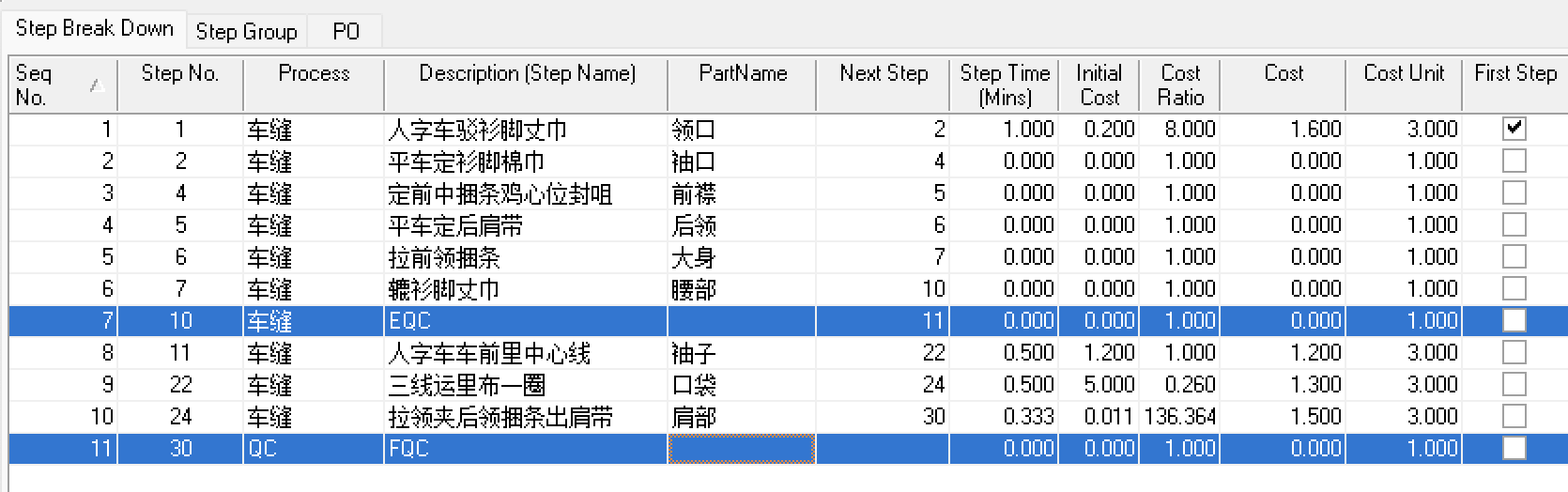

- 在生产单中加入相应工序,选择对应的“QC岗位工艺”,一个生产单可设置多个QC工序。

Add the corresponding steps to the work order and select the corresponding "QC WorkOperation". Multiple QC steps can be set for one work order.

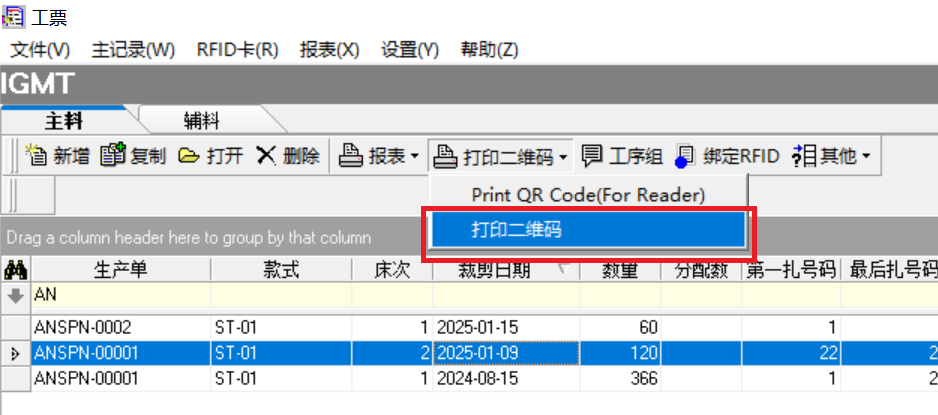

¶ 准备二维码 Prepare QR code

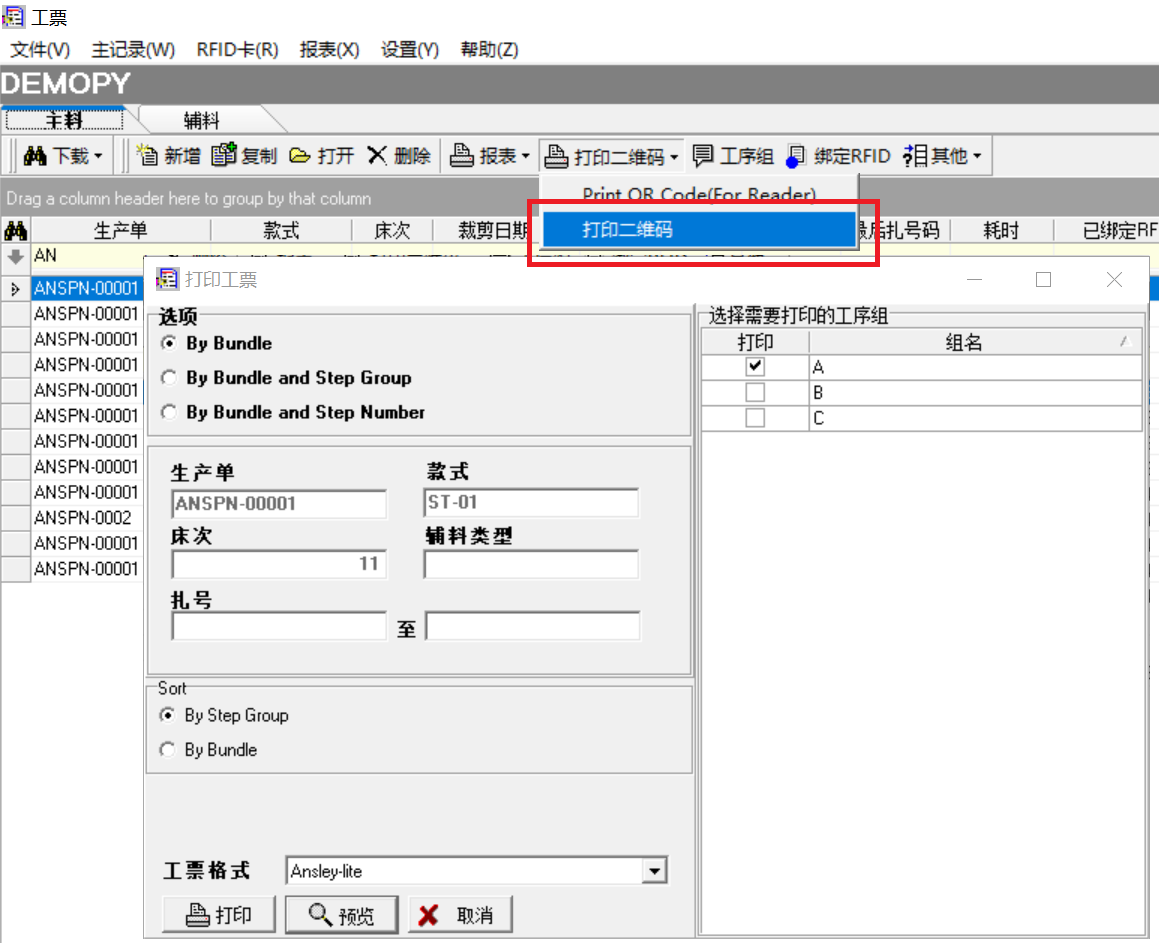

¶ 扎二维码 Bundle QR code

选中裁单点击 > 打印二维码 > 打印二维码,选择已设置好的二维码格式打印即可。

Select the cutting order, click "Print QR Code" > "Print QR Code" , and then select the pre - set QR code format to print.

注意:目前QC App仅支持 A.12345 这种格式的扎编码。

Note: Currently, the QC App only supports bundle codes in the format of A.12345.

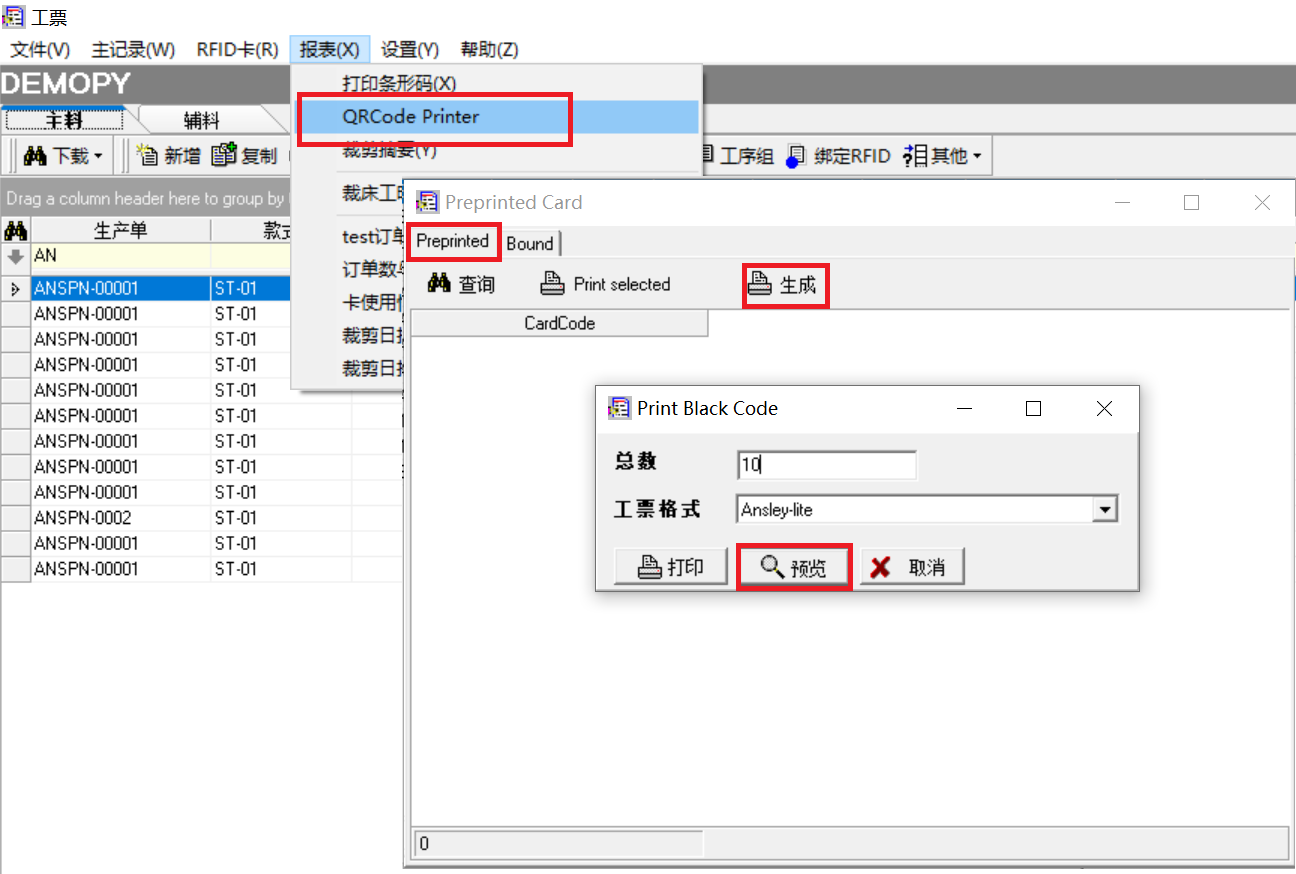

¶ 空白返工码 Blank Rework QR Code

在工票客户端 > 报表 > QRCode printer 中,点击“生成”,输入需要生成的空白返工卡数量,再点击预览/打印即可。

In the PMS Client "Ticket" > Report> QRCode printer, click "Generate", enter the number of blank rework cards to be generated, and then click "Preview/Print".

¶ QC员工设置与登陆 Setting and Logging in for QC worker

QC员工需在员工档案中勾选“质检员”。仅“质检员”员工可登陆QC App。

QC worker need to have "QC Inspector" checked in the employee profile. Only employees marked as "QC Inspectors" can log in to the QC App.

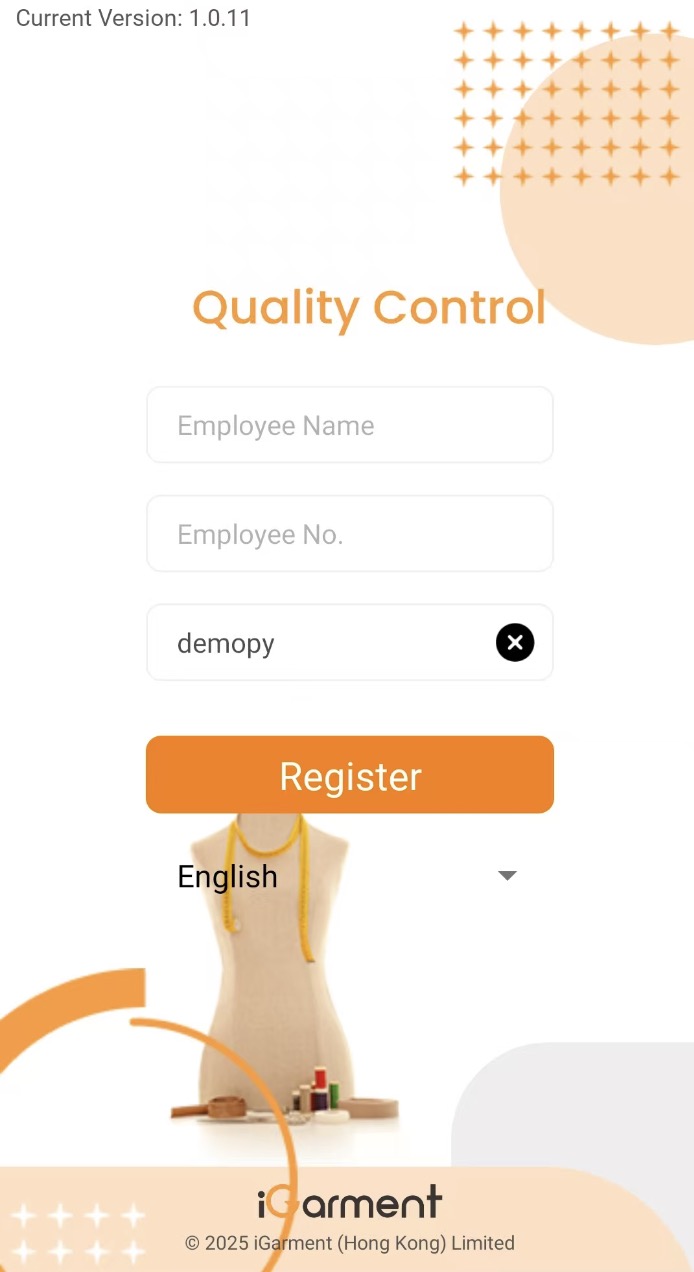

第一次登陆时,输入员工工号与姓名。

登陆服务器地址:数据库名称, 如:demopy

点击注册。手机的注册验证机制与iGarment其他App一致。

When logging in this app for the first time, enter the employee ID and name.

Login server address: DatabaseName, e.g., demopy

Click "Register" .The registration verification mechanism for mobile phones is the same as that of other iGarment Apps.

¶ QC App中录入质检结果 Recording Quality Inspection Results in the QC App

¶ 1. 选择检验工序 Select inspection step

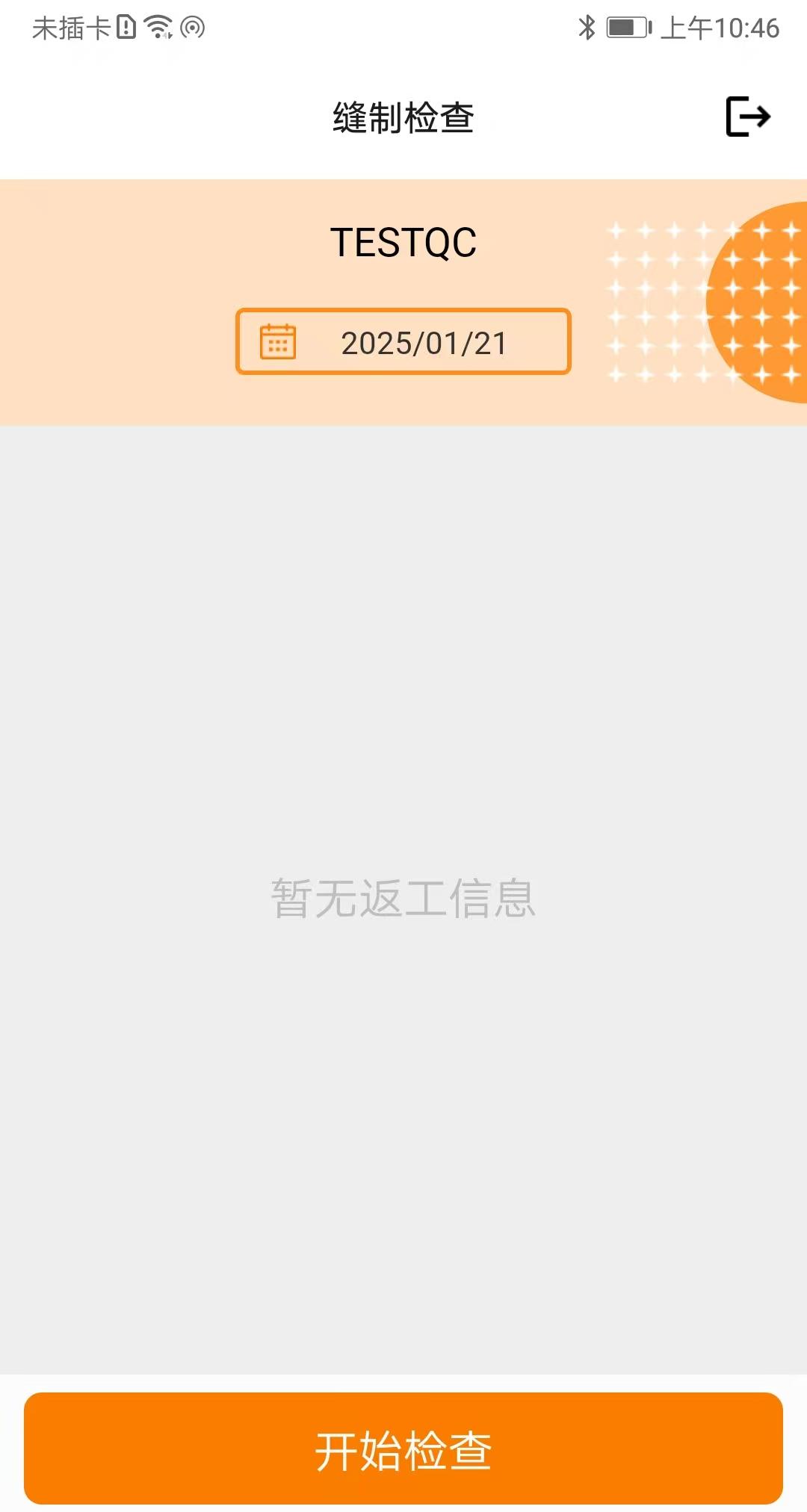

登入后,即可看到当前QC员工当日的QC记录。点击界面底部的“开始检查”,即可扫描扎二维码。

After logging in, you can view the QC records of the current QC worker for the day. Click "Start Inspection" at the bottom of the interface to scan the bundle QR code.

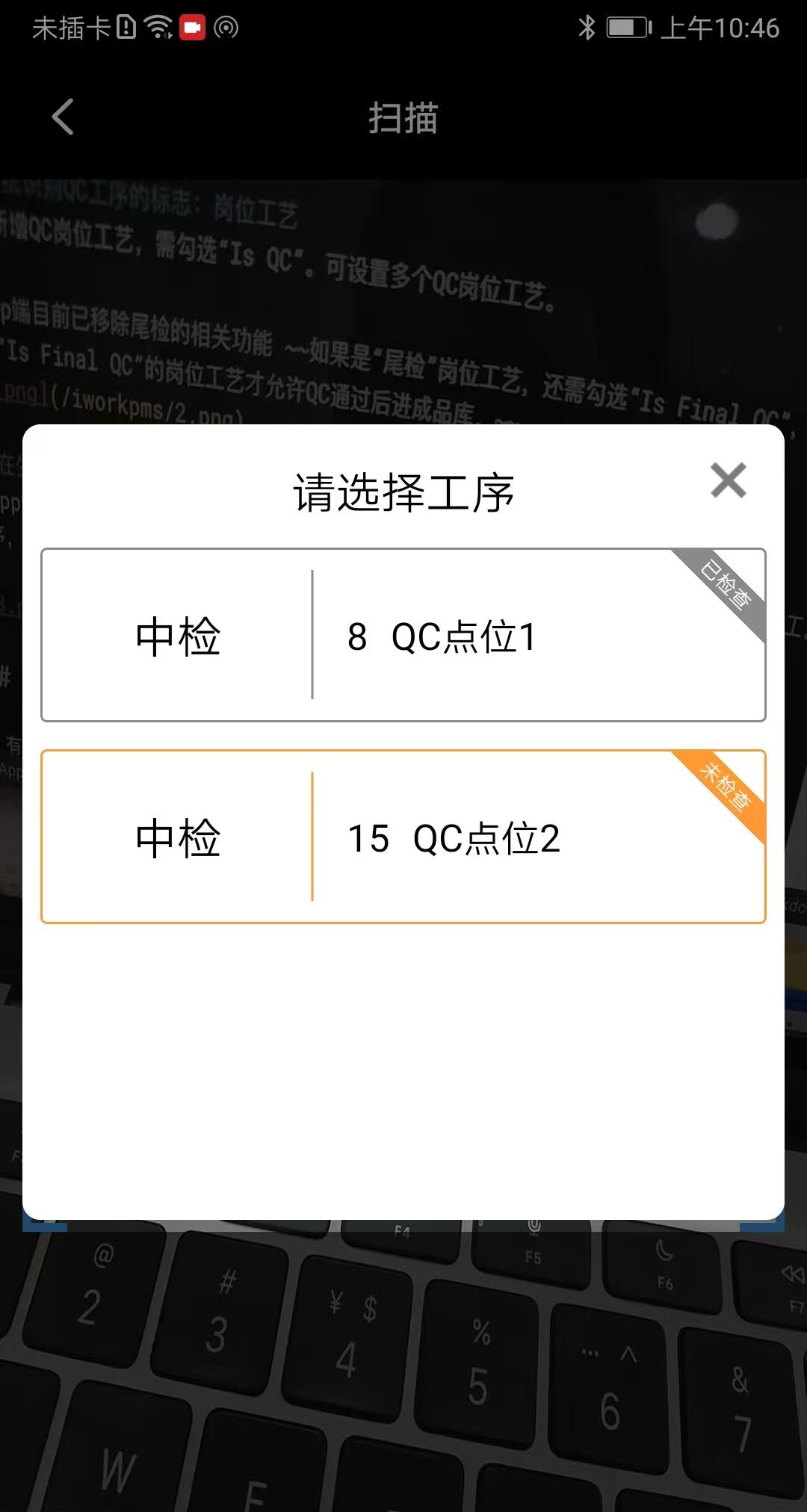

服务器会根据此扎已扫的前工序,来判断当前所扫的QC工序。需要注意的是:

The server will determine the current scanned QC process based on the previously scanned processes of this bundle. Note that:

- 如果勾选了“前工序是否必须扫”“前主要工序是否必须扫”,而当前QC工序之前还有未扫的工序,则会报错提示,且无法继续进行后续的QC操作。If "Must Scan Previous step" and "Must Scan Previous Main step" are checked, and there are un-scanned steps before the current QC step, an error will be prompted, and subsequent QC operations cannot continue.

- 如果当前QC工序已提交过检查结果,则提示当前QC工序已完成。If the inspection result of the current QC step has been submitted, it will be prompted that the current QC step has been completed.

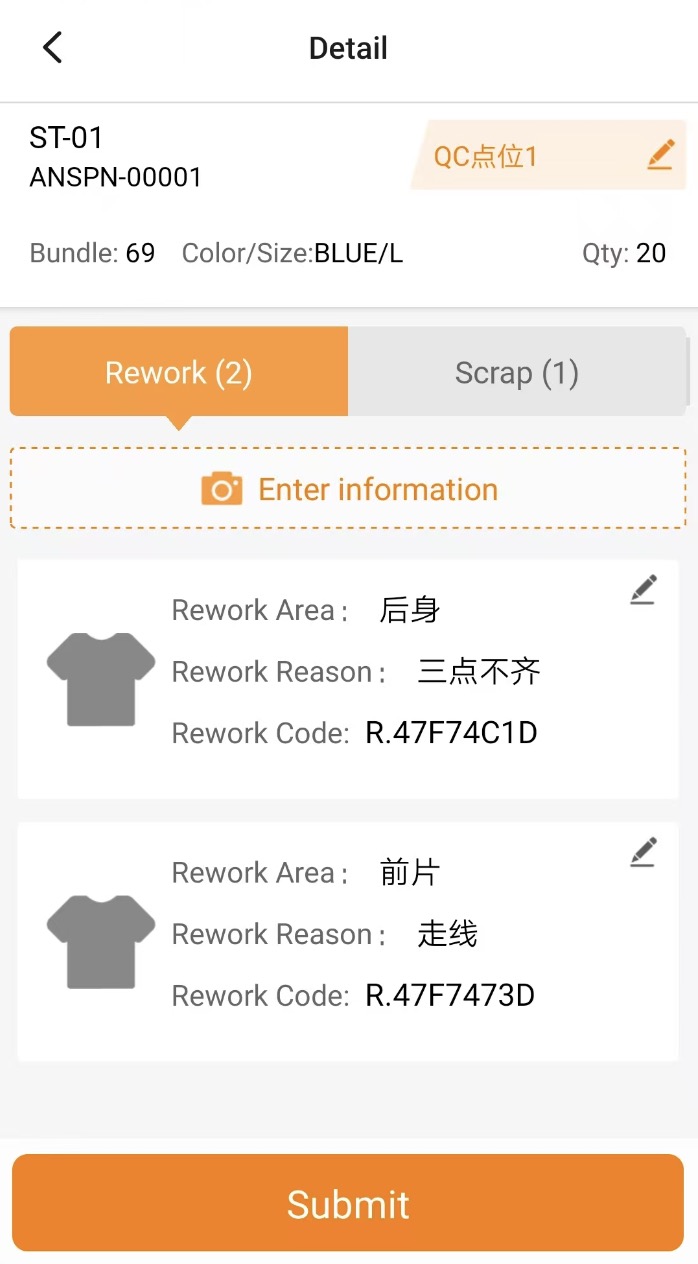

¶ 2. 录入质检结果 Record Quality Inspection Results

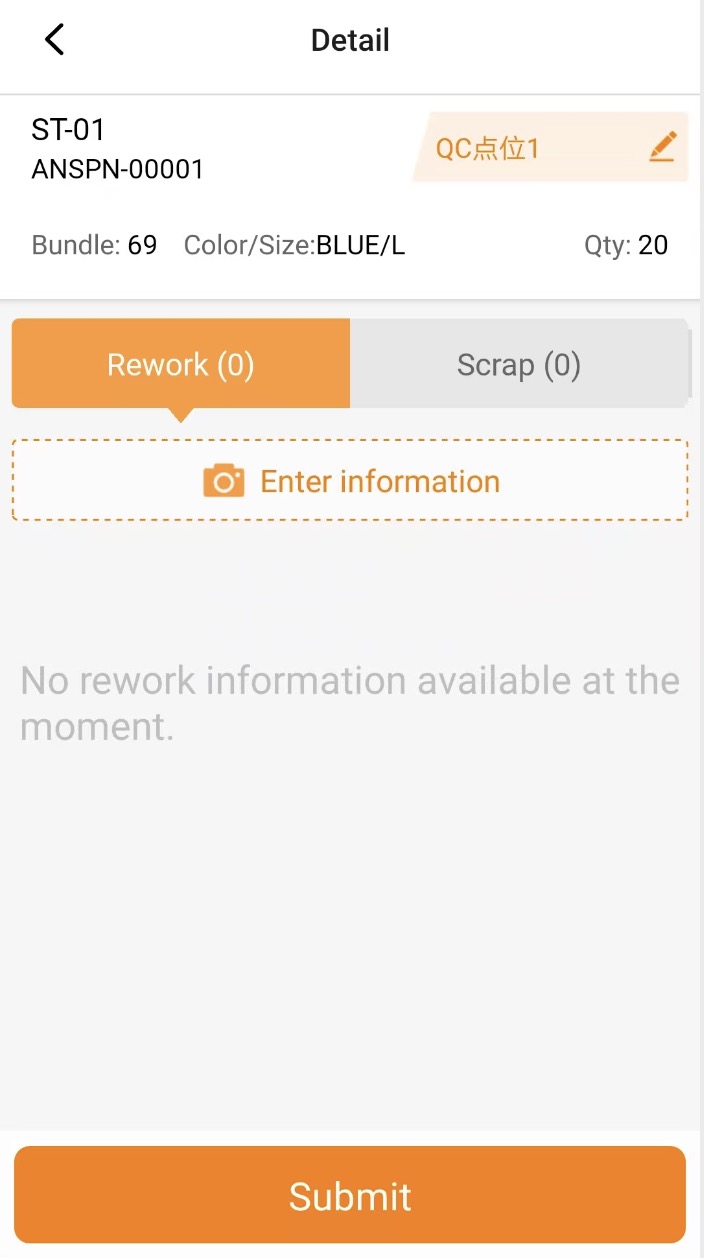

选择QC点位之后,即可开始录入质检结果。After selecting the QC point, you can start recording the quality inspection results.

如果一扎中有多件衣服存在质量问题,可逐件录入后,一起提交。未录入质量问题的数量,即认为是通过了此次质检。

If there are multiple clothes with quality problems in one bundle, you can record them one by one and then submit them together. The quantity of clothes without recorded quality problems is considered to have passed this quality inspection.

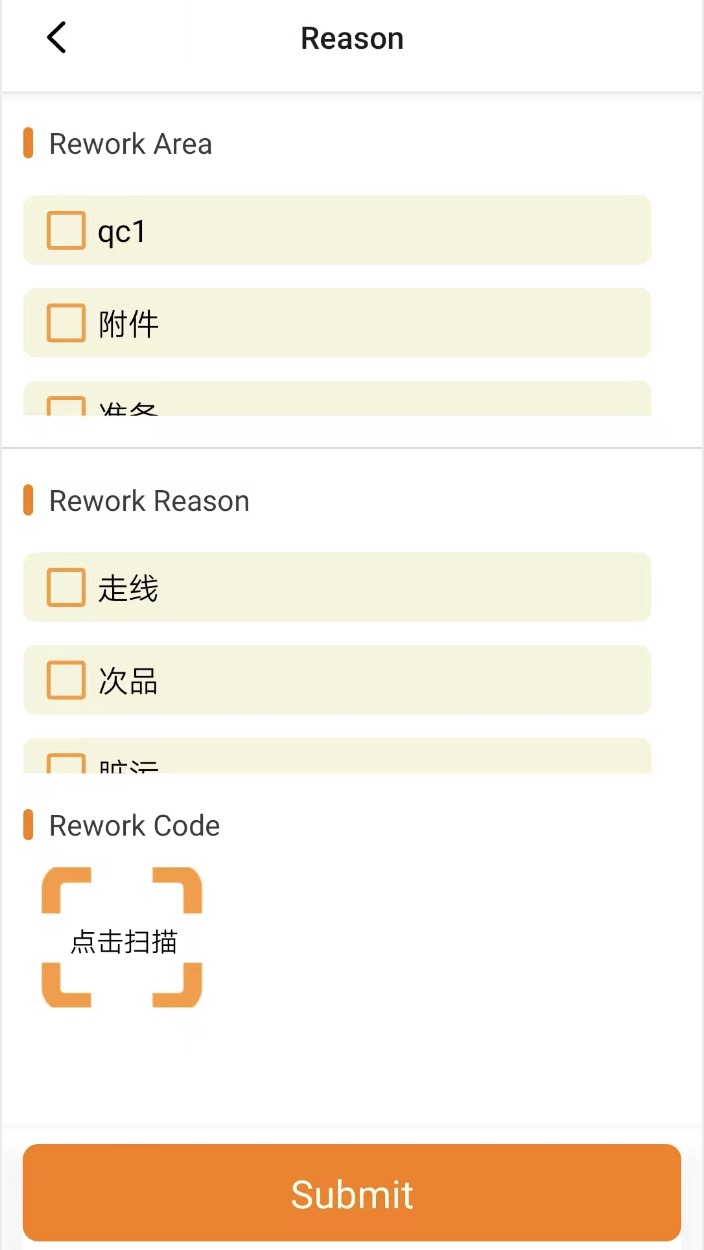

¶ 2.1 返工 Rework

在选中“返工”标签时,点击“录入信息”,可为瑕疵部位拍照,也可跳过。(目前照片仅可在app中查看)

之后根据实际情况选择返工部位与返工原因(可多选),注意:根据当前QC点位,程序可自动显示之前工序所对应的“部位”(在生产单工序表中定义)。如果工序表中未定义部位,则会自动显示部位主档案中定义的所有部位。

When the "Rework" label is selected, click "Enter Information", and you can take a photo of the defective part or skip it.(Currently, photos can only be viewed in the app.)

Then select the rework part and rework reason according to the actual situation (multiple selections are allowed). Note: According to the current QC point, the program can automatically display the "parts" corresponding to the previous processes (defined in the work order step list). If the parts are not defined in the process table, all parts defined in the main part file will be automatically displayed.

每件返工的衣服都需要绑定一张返工码(用于记录返工时间以及二次质检结果),点击界面下方的“点击扫描”按钮,扫描事先准备好的空白返工码(不可重复使用)。

点击“提交”,即完成一件需返工衣服的信息录入。如有多件需要返工的衣服,可再次点击“录入信息”,依次录入每件衣服的返工原因与返工部位,以及绑定返工码。

If you need to bind a rework code (used to record the rework time and the result of the second quality inspection), click the "Scan" button at the bottom of the interface to scan a pre-prepared blank rework code.

Click "Submit" to complete the information recording of one piece of clothing that needs rework. If there are multiple pieces of clothing that need rework, click "Enter Information" again to record the rework reasons and rework parts of each piece of clothing in turn and to bind rework code.

¶ 2.2 报废 Scrap

在选中“报废”标签时,点击“录入信息”,可为报废衣服拍照,也可跳过。选择缺陷部位与报废原因,提交即可。每次输入为报废一件衣服。

When the "Scrap" label is selected, click "Enter Information", and you can take a photo of the scrapped clothing or skip this step. Record the defective part and scrap reason then submit. Each input is for scrapping one piece of clothing.

¶ 3 返工后检验 Inspection after rework

返工后再次检验,与原扎检验是基本一致的。可直接扫描返工码,录入二次检验的结果。

同样支持通过,返工,报废三种检验结果。

需要注意的是,如果再次返工,需要绑定新的返工码,原返工码不可在用。

Inspection after rework again is basically consistent with the original bundle inspection. You can directly scan the rework code and enter the results of the secondary inspection.

It also supports three inspection results: pass, rework, and scrap.

It should be noted that if reworking again, a new rework code needs to be bound, and the original rework code can no longer be used.

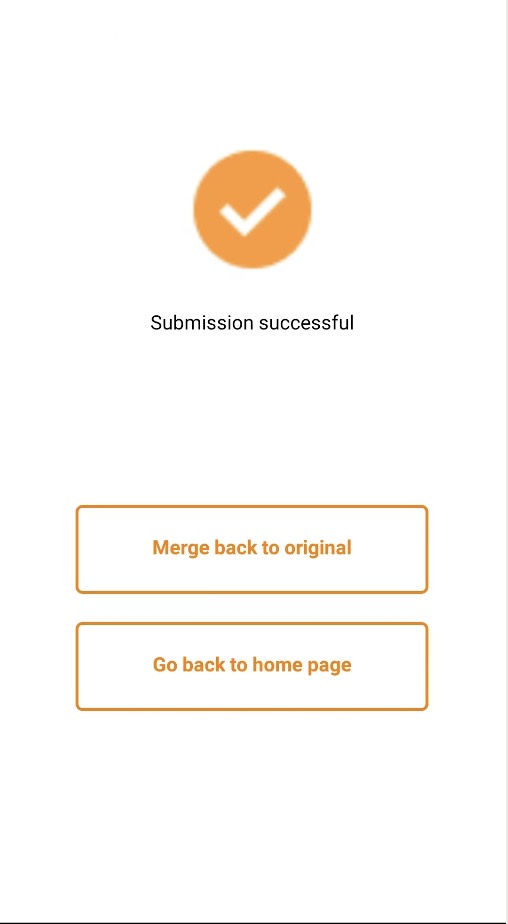

¶ 4 提交质检结果 Submit the Quality Inspection Results

所有需返工与报废的信息填写完毕之后,点击“提交”,即为提交整扎的质检结果。未录入的数量,即为通过。

注意:必须整扎录入完成之后,一次提交。

After filling in all the information about rework and scrap, click "Submit" to submit the quality inspection results of the whole bundle. The unrecorded quantity is the number of passed items.

Note: The whole bundle must be recorded and then submitted at one time.

提交时,会检查返工码是否已经被使用,如果已被使用会弹框提示,请重新绑定其他返工码。

When submitting, the server will check whether the rework code has been used. If it has been used, a pop-up prompt will appear, and you need to rebind another rework code.

如果返工回来的衣服再次检验的结果为通过,提交之后界面会询问是否将返工衣服数量合并回原扎:

- 点击“合并回原扎”:返工数量合并回原扎,当前返工二维码失效。

- 点击“返回主页”:返工数量不合并回原扎,可继续扫描当前返工二维码继续后续工作记录的提交。

If the reworked clothes pass the re-inspection, after submission, the interface will ask whether to merge the quantity of reworked clothes back into the original bundle:

- Click "Merge into Original Bundle": The reworked quantity will be merged back into the original bundle, and the current rework QR code will become invalid.

- Click "Return to Home": The reworked quantity will not be merged into the original bundle, and you can continue to scan the current rework QR code to submit subsequent work records.

如果原扎已经提交了后续工序的工作记录,则无法返回原扎。

If the original bundle has already submitted work records for subsequent processes, it cannot be returned to the original bundle.

目前Inspection app支持的是A.BundleID 格式的QR code

而Reader是支持的是通过随机生成的虚拟Rfid编码而生成的QR code

如果客户缝制线使用的是Reader,则返工码无法继续往后流转,必须返回原扎。

Currently, the Inspection app supports QR codes in the format of A.BundleID, while Reader supports QR codes generated from randomly generated virtual RFID codes. If the customer's sewing line uses Reader, the rework QR code cannot flow further and must be returned to the original bundle.

¶ 5. 查看与删除 Preview & delete

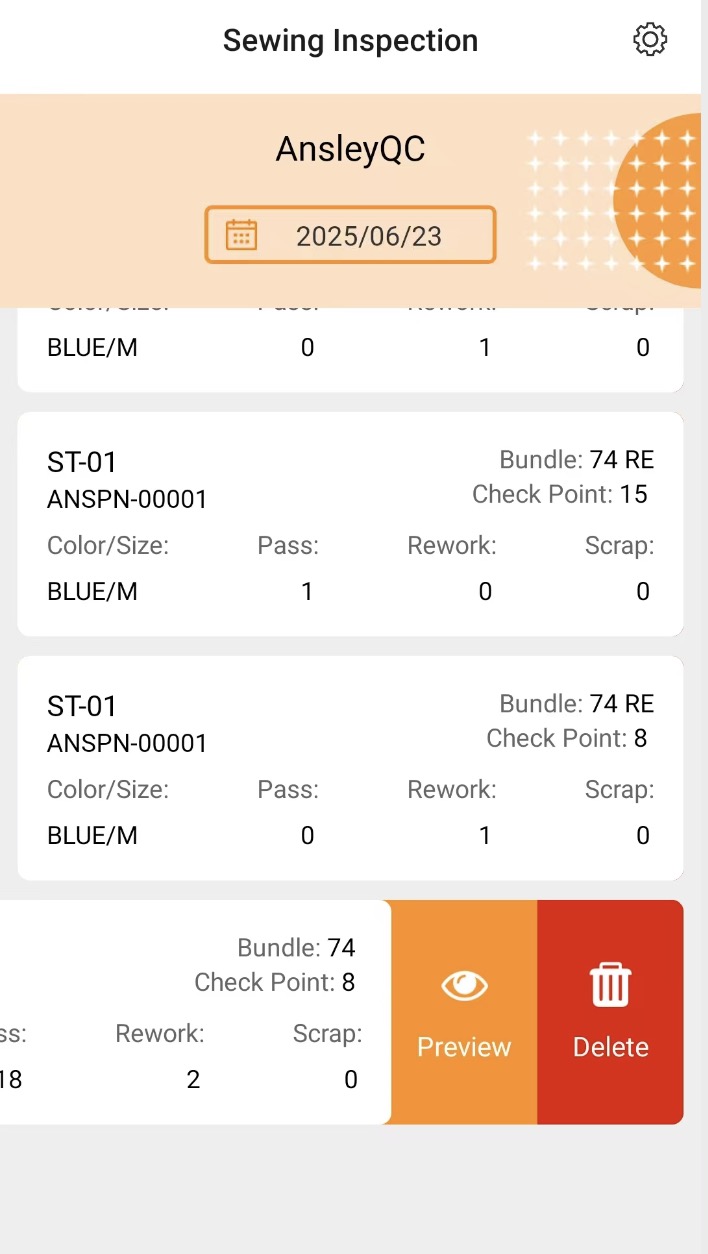

在首页可看到当前所有的检查记录,也可点击“日期”,查看其他日期的检查记录。

按住某一检查记录向左滑动,可调出“查看”与“删除”按钮。

点击 “查看” 按钮,可查看该条检查记录的详细信息。

点击 “删除” 按钮,可删除当前检查记录。但需要注意的是,以下情况不允许删除:

- 如果此扎在此条检查记录之后,又登记了后续工序的工作记录,则不允许删除此条检查记录。

- 如果此条检查记录中有返工,且已经对返工衣服做了二次检查的话,则不允许删除此条检查记录。

- 如果返工衣服的二次检验结果为通过,想删除此条通过记录的话,需原返工码没有被绑定到其他扎上。

On the home page, you can view all current inspection records. You can also click "Date" to check inspection records for other dates.

Press and hold an inspection record and swipe left to bring up the "Preview" and "Delete" buttons.

- Click "Preview" to view detailed information of the inspection record.

- Click "Delete" to delete the current inspection record. Note that deletion is not allowed in the following cases:

- If this bundle has registered work records for subsequent processes after this inspection record, this inspection record cannot be deleted.

- If this inspection record involves rework and the reworked clothes have undergone secondary inspection, this inspection record cannot be deleted.

- If the secondary inspection result of the reworked clothes is "Pass" and you want to delete this pass record, the original rework code must not have been bound to another bundle.