¶ 简介

Sewing Work Input App 服装工厂缝制报产手机软件(以下简称SWI)

作为PMS系统的数据采集工具之一,工人可通过手机扫描二维码工票,实现自主上报产量数据。

- 方便管理层轻松掌握生产进度,及时发现问题;

- 工人也可通过手机软件查看当前薪期或过往薪期的工作与计件工资记录。

- 支持「按扎扫码」,以及「按工序扫码」,两种操作模式。

As one of the data collection tools of the PMS system, workers can scan the QR code ticket through their mobile phones to independently report output data.

- It is convenient for the management to easily grasp the production progress and find problems in time;

- Workers can also view their work and piece-rate wage records for the current or past pay periods through the mobile app.

- Support "press to scan the code" and "scan the code according to the process", two operation modes.

¶ 安装注册与更新

SWI目前支持安卓v10及以上手机操作系统。

第一次使用时,可通过实施工程师提供的链接下载并安装程序。安装成功后,在桌面双击以下图标打开程序。

SWI currently supports Android v10 and above mobile operating systems.

The first time you use it, you can download and install the program through the link provided by the implementation engineer. After successful installation, double-click the following icon on the desktop to open the program.

当您第一次登陆我司App产品,或者更换手机登陆,需事先与贵司管理员确认,是否已允许当前员工登陆App。

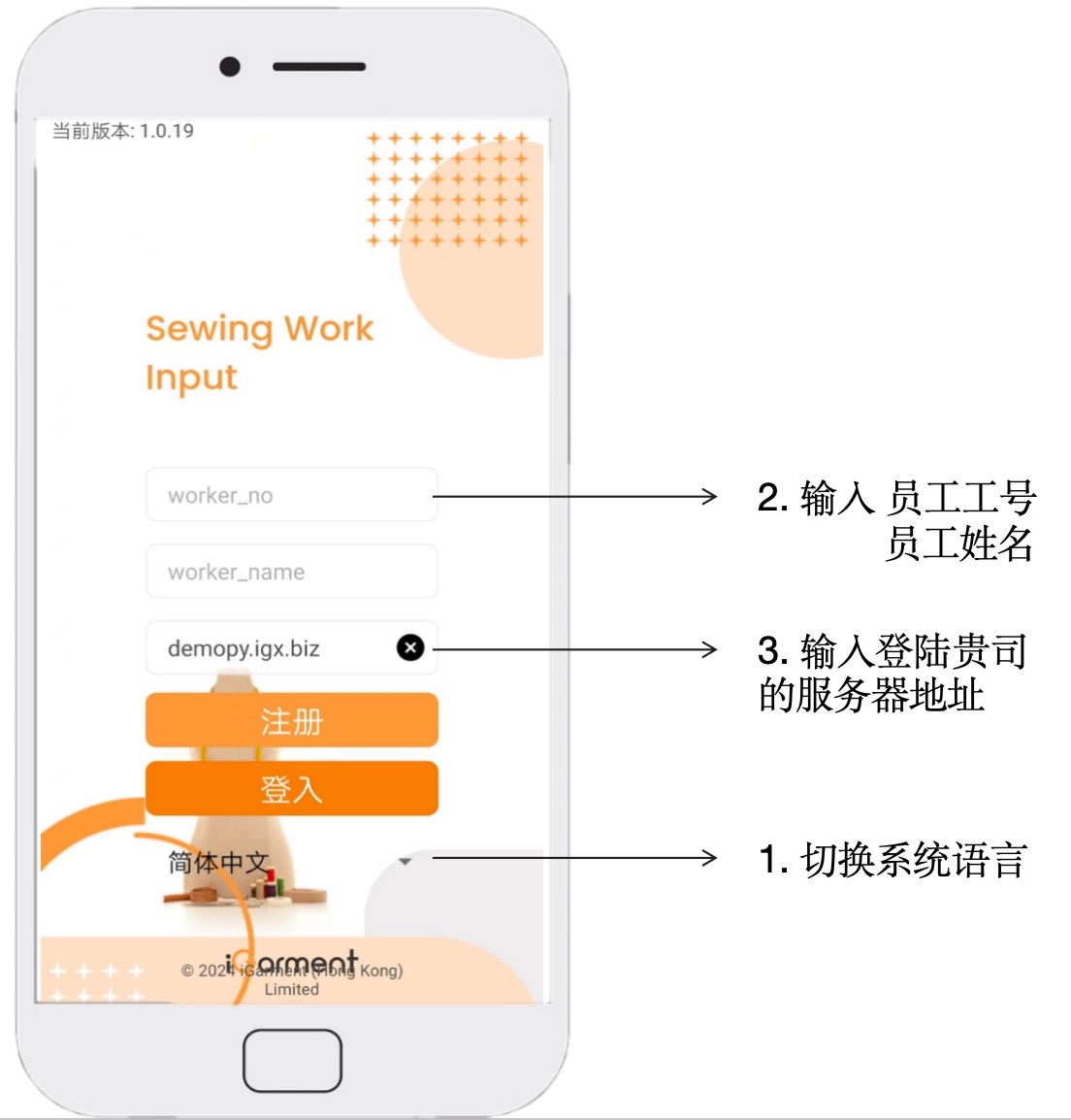

双击打开程序后,可以先点击底部的语言选择框,选择您所使用的语言,目前我们支持:英语,简体中文,繁体中文三种语言。

再依次填入您的工号,姓名,与贵司的服务器地址(具体可询问实施工程师或贵司的项目负责人)点击注册即可。

When you log in to our App products for the first time, or change your mobile phone to log in, you need to confirm with your administrator in advance whether the current employees have been allowed to log in to the App.

After double-clicking to open the program, you can first click the language selection box at the bottom and select the language you use, currently we support: English, Chinese Simplified Chinese, Chinese Traditional three languages.

Then fill in your job number, name, and your company's server address (you can ask the implementation engineer or your company's project leader for details) and click Register.

注册成功之后,您今后打开程序只需直接点击登入即可。

Once you have successfully registered, you can open the program in the future by simply clicking on Login.

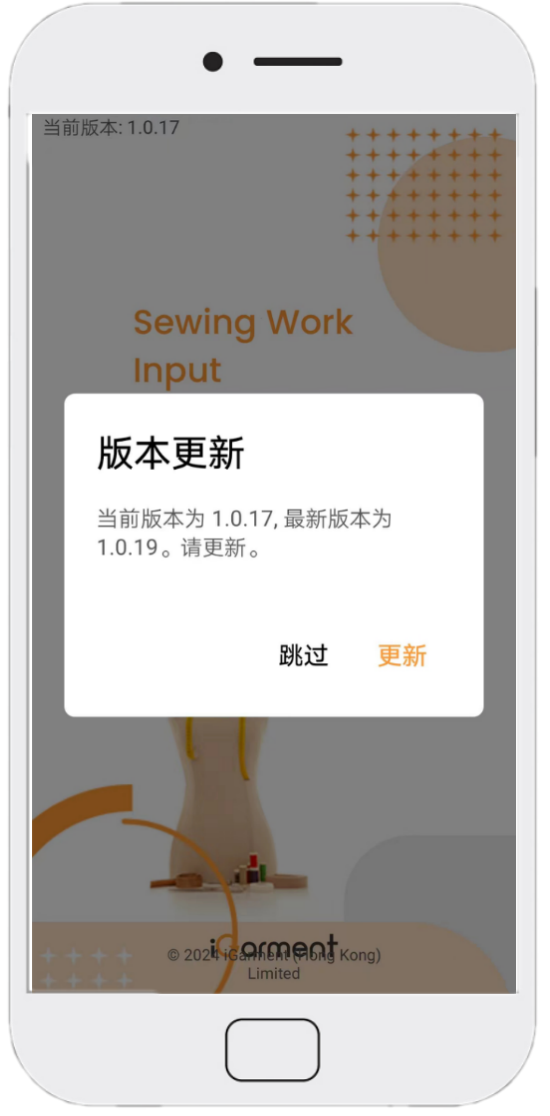

当程序升级时,您打开时会看到提示,点击“更新”即可下载到最新的安装包,安装后即可登入。

注意:如果您当前版本已经低于最低版本,您必须更新后才可进入程序。

When the program is upgraded, you will see a prompt when you open it, click "Update" to download the latest installation package, and you can log in after installation.

Note: If your current version is lower than the minimum version, you must update before you can access the program.

¶ 扫描工票

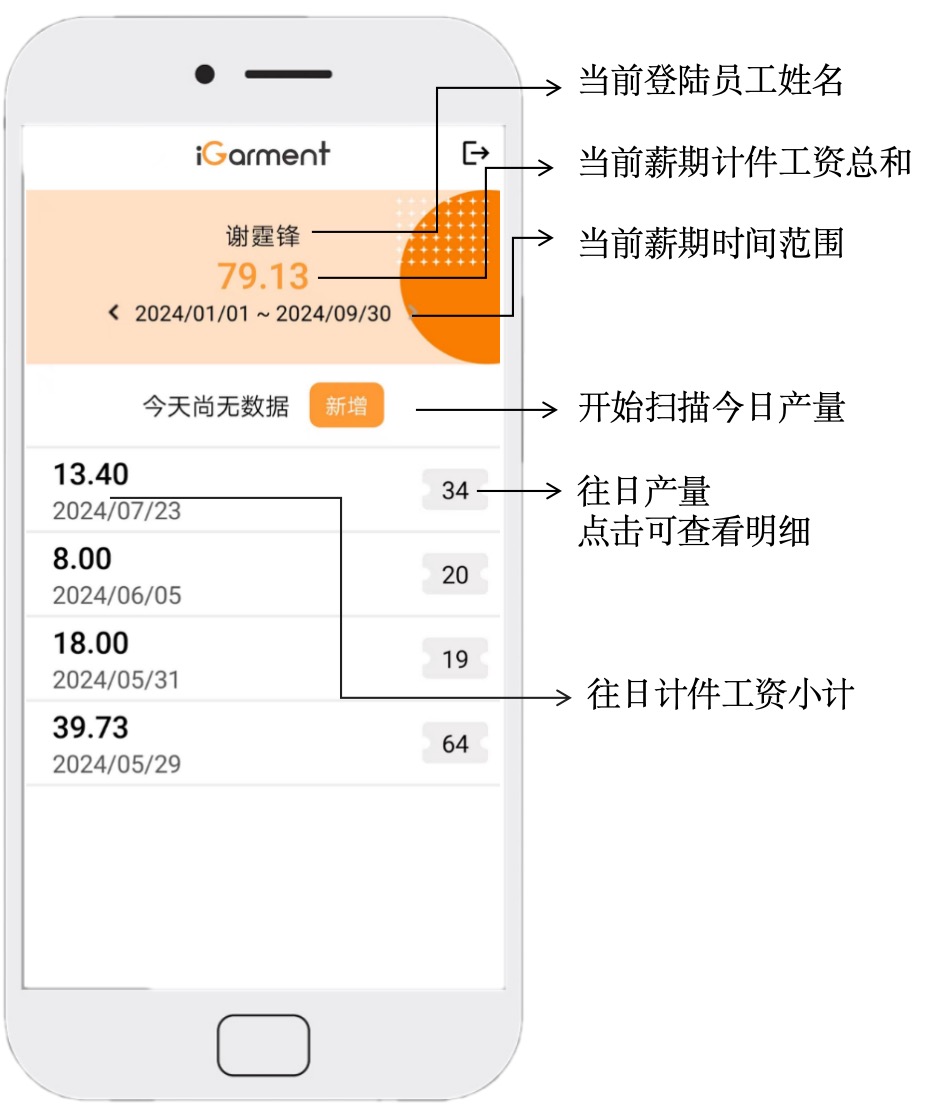

您登陆成功之后,在屏幕上方可以看到当前薪期的计件工资总和,下方可以看到每天的工作数量与计件工资小计。

After you log in successfully, you can see the sum of the piece-rate wages for the current pay period at the top of the screen, and you can see the number of jobs per day and the subtotal of the piece-rate wages below.

点击某个日期行,可以看到这一天的扫码报产明细。每条记录右端的“垃圾桶”按钮可以删除此条记录。

如果您打开的是当日明细,可以点击屏幕底部的“新增”按钮继续扫描工票。如果是往日明细,则不允许新增,即不允许补扫过往工票。

Click on a date row to see the production details of the scan code for this day. The "Trash" button at the right end of each record can be used to delete the record.

If you have a day's history open, you can click the "Add" button at the bottom of the screen to continue scanning the ticket. If it is a past detail, it is not allowed to add it, that is, it is not allowed to re-scan the past ticket.

SWI的工票扫描支持按扎扫码实时报产,以及按工序扫码非实时报产,两种操作模式。具体使用哪种模式是由您所在工厂管理流程所决定。

SWI's ticket scanning supports real-time production reporting by scanning the code and non-real-time production reporting by scanning the code according to the process, two operation modes. Which model to use depends on your plant management processes.

¶ 按扎扫码实时报产

如果您所在工厂选择的是按扎扫码实时报产的模式,您在扎包上只会看到一张二维码的工票。您需要在每扎开始生产前,扫描此二维码。

扫描成功后,屏幕上会显示当前扎的基本信息(款号,生产单号,颜色尺码数量等),以及工序列表。

If your factory chooses the mode of pressing the QR code to report production in real time, you will only see a QR code ticket on the bag. You need to scan this QR code before each bundle starts production.

After successful scanning, the basic information of the current tie (style number, production order number, color size quantity, etc.) will be displayed on the screen, as well as the process list.

需要注意的是:

- 该扎已经被注册的工序,不会显示

- 如果组长已经做了工序指派,将默认将指派给您的工序勾选上。

- 您可以根据实际情况修改工序选择。

- 下次扫描相同生产单款式时,会默认勾选您上一扎的选择。

确认无误后,点击下方的提交按钮即可。

您的工序生产完成后,请您将此二维码仍绑在扎包上,随扎包一同流向后面工序的同事。

It is important to note that:

- The process that has already been registered will not be displayed

- If the team leader has already assigned an operation, the assigned process to you will be selected by default.

- You can modify the operation selection according to the actual situation.

- The next time you scan the same production single style, your previous selection will be checked by default.

Once you've confirmed that everything is correct, click the submit button below.

After the production of your process is completed, please tie this QR code to the tie bag and flow to the colleagues in the later process with the tie bag.

¶ 按工序扫码非实时报产

如果您所在工厂选择的是按工序扫码非实时报产的模式,您在扎包上会看到一叠二维码的工票,每张工票上会有对应的款号,扎号与工序号。

您可将您负责生产的工序号对应的工票撕下,保存妥当,待空闲时统一扫描报产即可。

If your factory chooses the mode of scanning the code by process and not reporting production in real time, you will see a stack of QR code tickets on the bag, and each ticket will have the corresponding model number, tie number and process number.

You can tear off the work ticket corresponding to the process number you are responsible for producing, save it properly, and scan it for production when you are free.